When a structure fails, the event itself is tragically swift. But the reasons for failure are often written slowly, over decades, in a language of chemical reactions and microscopic stresses. The 2021 collapse of Champlain Towers South was a stark reminder that the story of a building’s demise is ultimately told by its materials. Forensic investigation into the concrete and steel revealed a history of vulnerabilities, including design flaws and construction issues, that went unseen until it was too late. This highlights a key mission for the engineering community: we must become fluent in the language of our materials, not only to understand the past but to responsibly build the future.

Decoding the past: The power of forensic analysis

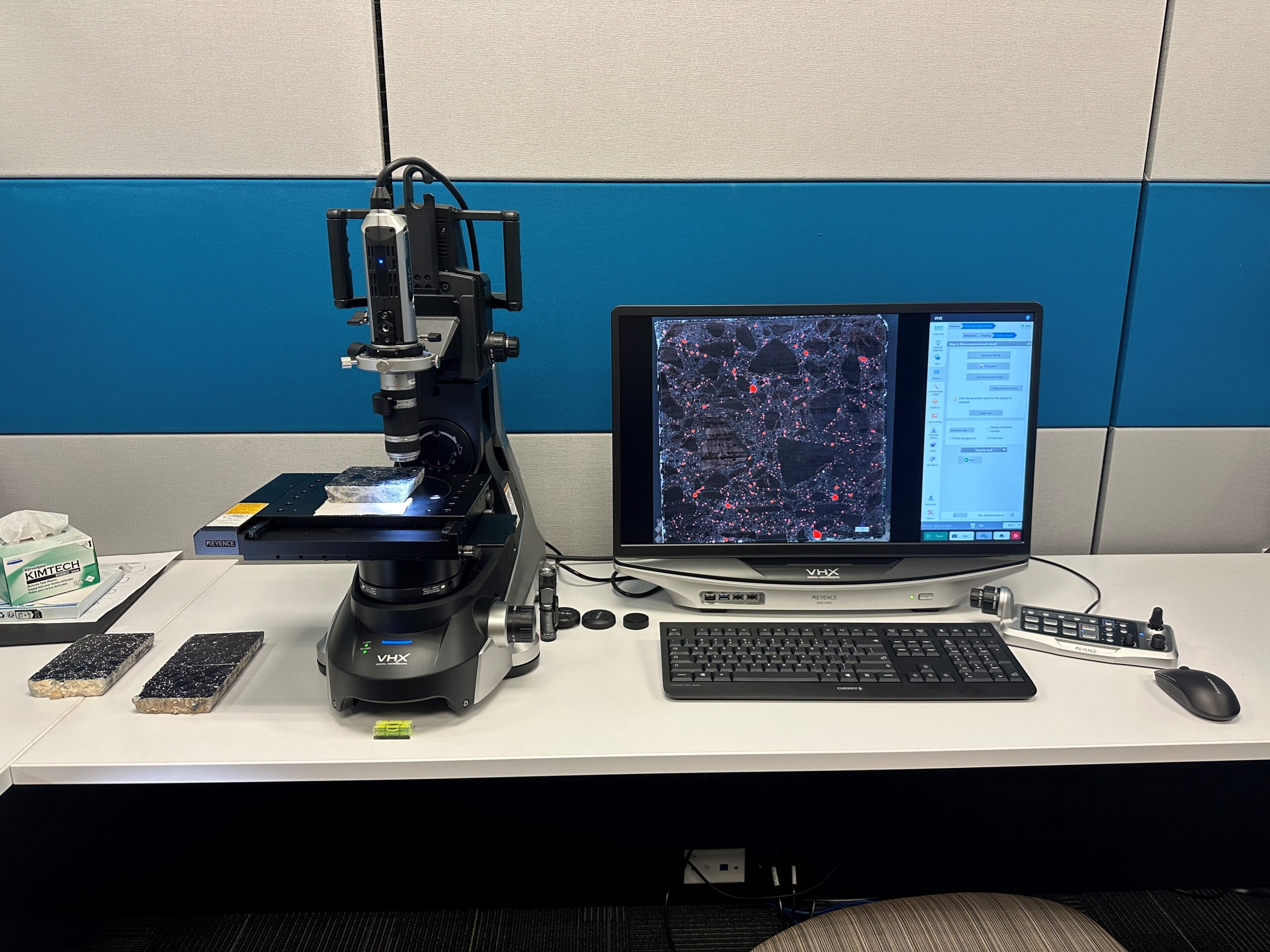

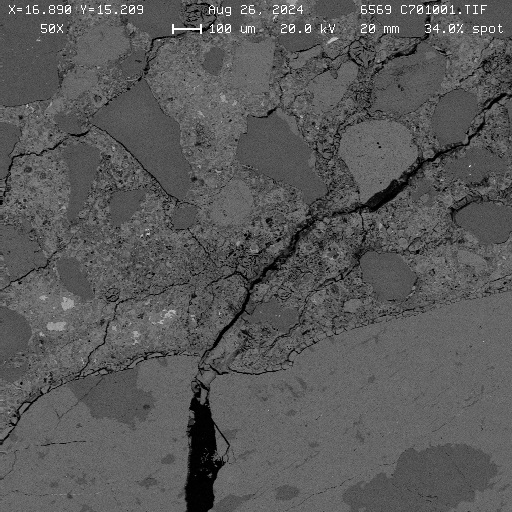

The modern materials science lab acts as a forensic library for the built environment. Through advanced analytical techniques like petrography—the microscopic examination of concrete—engineers can look back in time to diagnose the root causes of degradation. This deep analysis is fundamental to the stewardship of our existing infrastructure.

By identifying the subtle signs of alkali-silica reactions, mapping the invisible pathways of chloride intrusion, or assessing fire damage at a microstructural level, the lab provides the data needed to evaluate the viability and remaining service life of a structure. This forensic insight is the first step in successful restoration, providing a data-driven foundation for extending the life of our built world.

Why this matters: Forensic analysis moves beyond guesswork. It provides the material truth required to make sound engineering judgments, helping to guide investments in the restoration and preservation of existing buildings in ways that are effective and durable.

The lessons drawn from failures of the past don’t just protect existing structures—they also pave the way for innovation in new construction.

Inventing the future: The lab as an R&D partner

Insights from forensic investigations directly inform how we approach the future of construction. A wave of material innovation is providing new tools, but these advancements require rigorous research and development.

Artificial intelligence is now designing novel concrete mixes with unprecedented sophistication. Meta’s AI tool, for instance, is already creating lower-carbon concrete formulations for its data centers, while researchers at the University of Southern California are using AI to design materials that can self-heal and actively capture carbon. In parallel, real-world applications of graphene-enhanced concrete are achieving significant CO₂ reductions without sacrificing strength, and self-healing bioconcretes are moving from the lab to the job site, with a market projected to exceed $280 billion by 2029.

Why this matters: Innovation without validation is a liability. An advanced materials science lab provides independent, scientific verification to confidently select and specify advanced materials, making sure that next-generation structures are built with proven, reliable technology.

As new and old materials converge, the greatest opportunity lies in bringing them together; making the future of construction both innovative and sustainable.

Bridging old and new: The science of adaptive reuse

This dual expertise; understanding the past and validating the future; converges in one of the most pressing challenges for the built environment: creating a truly circular economy through the adaptive reuse of existing structures.

A materials science lab provides the necessary link. Forensic analysis of an existing building establishes a baseline of its material health and structural capacity. This data then informs the selection of advanced materials for strengthening, restoring or expanding the structure. This integrated approach, where forensic data guides the application of innovative materials, is the key to extending the life of buildings, reducing waste and creating a more resilient and sustainable future.

Why this matters: Adaptive reuse is one of the most sustainable practices in construction. A materials science lab provides the integrated intelligence; combining forensic investigation with new material evaluation; that makes it possible to transform aging assets into high-performing, modern structures.

The road ahead

As an industry, we face a defining question: Are we prepared to integrate the lessons from material failures of the past with the complex innovations of the future? The answer depends on our ability to understand the material truth.

It requires a new generation of leadership from professionals who possess a rare blend of deep laboratory expertise and practical field experience. Materials science leaders like April Snyder, Blake Restelli, PG and Andrei Ramniceanu, PhD, PE are positioned at the intersection of forensics, innovation and restoration. They, and others like them, are guides for navigating this complex but exciting new era for the built environment.

About the Author

Jigar Desai, PhD, PE, MBA is a Principal and Regional Manager of Facilities Consulting at ECS Group of Companies. Based in Philadelphia, he leads multidisciplinary teams to deliver innovative engineering solutions and drive strategic growth across the Mid-Atlantic region. With a PhD in Civil Engineering and an MBA from Villanova, Jigar combines technical expertise with business acumen to advance ECS’ core values of collaborate, focus and lead.

References

- Fadden, M., Iodice, S., & Klein, G. (2025, April). The Champlain Towers South collapse: A forensic engineering analysis. STRUCTURE Magazine. Read more

- National Institute of Standards and Technology. (2025, June 23). NIST Releases Extensive Video Update on Champlain Towers South Investigation. Read more

- ForensisGroup. (n.d.). Champlain Towers South Collapse: Building and Structure Failures, Legal Consequences, and Safety Lessons. Read more

- Kusuma, J., Ament, S., Bakshy, E., & Ayala, R. (2025, July 16). Using AI to make lower-carbon, faster-curing concrete. Meta Engineering Blog. Read more

- University of Southern California. (2025, July 23). Concrete that lasts centuries and captures carbon? AI just made it possible. ScienceDaily. Read more

- University of Manchester. (2025, July 29). Graphene-enhanced, low-carbon concrete successfully laid at Northumbrian Water site. Read more

- The Business Research Company. (2025, July). Self-Healing Concrete Global Market Report 2025. Read more

- Shah, P. (2025, April 4). How the Construction Sector Can Transition to a Circular Economy. Building Material Reporter. Read more

- European Circular Economy Stakeholder Platform. (2025, March 26). Circularity in the built environment: A Reading Guide. Read more