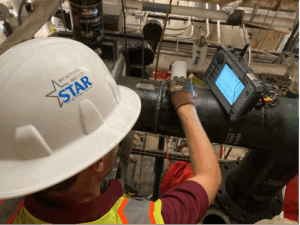

ECS Group of Companies (ECS) applies nondestructive evaluation (NDE) to verify integrity and detect flaws without cutting, coring or taking systems out of service. From structural steel to concrete, roofs and subsurface utilities, our technicians use proven methods to help you meet code, reduce risk and make informed decisions.

NDE is a toolset integrated across ECS’ disciplines. Whether your project involves new construction, maintenance or forensic evaluation, we select the right method for your goals and deliver actionable results that keep work moving.

CONTACT US

ECS Group of Companies (ECS) applies nondestructive evaluation (NDE) to verify integrity and detect flaws without cutting, coring or taking systems out of service. From structural steel to concrete, roofs and subsurface utilities, our technicians use proven methods to help you meet code, reduce risk and make informed decisions.

NDE is a toolset integrated across ECS’ disciplines. Whether your project involves new construction, maintenance or forensic evaluation, we select the right method for your goals and deliver actionable results that keep work moving.

CONTACT US