ECS is proud to have so many veterans apart of our team in a variety of positions across the company! This Veterans Day we would like to spotlight a few of them and highlight lessons they learned from their time serving in the United States military.

Kelly Truesdale Dahl, ECS Tampa, United States Marine Corps

“I learned from the Marine Corps to embrace the suck or in other words welcome the pain. The drill instructors showed us through our training and constant obstacles we had to overcome, that your mind will quit before your body will. So, always keep pushing no matter how much it sucks, no matter the pain because in the end it will absolutely be worth it.”

Tim Ellerbe, ECS Oklahoma City, United States Army

“If I learned one thing above all else over there, it’s that life is short, and we should appreciate the time we have here and make the most of it because nothing is guaranteed.”

Michael “Mack” McMackin, ECS Baton Rouge, United States Army

“On time is late. Clean equipment doesn’t malfunction.”

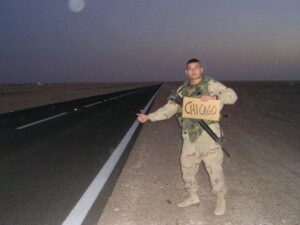

Dave Ball, ECS Fredericksburg, United States Army

“Seeing the progress from my first day in, to this picture is astounding. I never thought I would be in that position which made me learn to never doubt my abilities and motivation. Seeing who I was and what I became is a night and day difference. Joining the military was the smartest decision I ever made.”

Denis Columbare Jr., ECS Mid-Atlantic Facilities, United States Marine Corps

“The best lesson I learned from my time serving is that with hard work, determination, and a relentless drive to succeed, you are capable of things far exceeding what you thought you were capable of.”

Jad Sobh, ECS Southeast, United States Army

“When you are faced with a challenge, often times your limits are far beyond what you think. Keep your head down and push through because you’ll almost always surprise yourself.”

Jacob Pitner, ECS Raleigh, United States Army

“During my 13 years in the military I learned two main things: One, to embrace change or as we say embrace the suck, things change on a whim. Two, what it is to be an effective leader and accomplish the mission.”

Garret Klingensmith, ECS Oklahoma City, United States Marine Corps

“The biggest thing I probably learned from my time in the Marines is that what I think my limitations may be, are likely incorrect. I learned I could do so much more and endure more and accomplish more than what my body or mind tells me.”

Craig Hiatt, ECS Southwest Environmental, United States Coast Guard

“My experience in the USCG taught me the values of teamwork, responsibility, dependability, and accountability. It is no coincidence that these are the values we value here at ECS. I can honestly say that I would not be the husband, father, or leader I am today had it not been for my time in the Coast Guard.”

Christopher Sommer, ECS Mid-Atlantic Environmental, United States Army

“During my 23 years in the military, I learned how to operate (and thrive) under extreme pressure in austere and rapidly changing environments.”

Joseph Nestor, ECS Southeast Environmental, United States Coast Guard

“It takes a team with diverse skills to complete difficult missions.”

Benjamin LaPointe, ECS Midwest Environmental, United States Army

“I learned that there is a lot at home that I took for granted.”

Rob Gudz, ECS Mid-Atlantic, United States Army

“I learned that as a leader you should always take care of your people, before yourself. Be the first one awake, the last one asleep. Always show up on time, with the proper equipment and in the proper uniform. All are as applicable today as when I was in the Army.”

Cory Dwyer, ECS Wilmington, United States Marine Corps

“JJ DID TIE BUCKLE… that’s the acronym we used in boot camp to memorize the 14 leadership traits of a Marine. Justice, judgement, dependability, integrity, decisiveness, tact, initiative, endurance, bearing, unselfishness, courage, knowledge, loyalty and enthusiasm. Those traits were instilled in me and live strong to this day.”

John Hicks, ECS Florida, United States Army

“During my military career there have been many times where I have been “in the suck” and this experience has taught me to never give up, never quit, never leave behind a fallen Soldier and to persevere even when things look really bad. Through that determination, I have found that you can fight through any bad spot you are in. This has translated into being persistent with helping my team and my clients out and having “their six” when they are in a tough spot. Having the confidence of knowing that no matter how bad a situation may be, that if you attack it early and get ahead of it, you will more than likely solve the problem.”

Ben Temple, ECS Southeast, United States Army

“I’m thankful that I had the opportunity to serve with so many great people. What I learned from the military is that leadership is all about listening to and taking care of people, whether they are soldiers, technicians, engineers or scientists.”

Michael Rayl, ECS Mid-Atlantic, United States Army

“Learn from the experiences and knowledge of others whenever possible, but also teach others your experiences and knowledge whenever possible.”

William Gaspar, ECS Mid-Atlantic, United States Army

“From Dessert Shield and Storm to managing an office, it remains the same: training, planning, and ensuring you are in the front leading your staff. It requires all to succeed.”

ECS would like to send out a huge thank you to all our veterans for your sacrifices and service to our country!

Here are a few bonus photo submissions!

Charlie Gresser, ECS Milwaukee, United States Marine Corps

Dylan Adkins, ECS Raleigh, United States Marine Corps