Typically, industry professionals draw on their experience, published data and predictive equations to estimate magnitudes of vibrations to understand how much vibration from your jobsite’s construction activities may affect adjacent/nearby structures. What do you do when there is no published data related to the work you would perform or when unique building and site conditions are present? How do you know if the published data can be relied upon for your site? Thankfully, there are other ways to estimate vibrations from construction. A site-specific attenuation study can help you estimate the magnitude of vibrations likely to be experienced by others, with data measured specifically for your jobsite operations and site conditions. The study is used to confirm industry references are valid for your site and will help provide feedback when such data is simply not available.

As construction equipment is mobilized to a site, the associated testing for the site-specific study can be performed. Seismographs, also known as vibration sensors, are placed at different distances from the construction equipment. Operators run the construction equipment, performing different operations to mimic operations planned during construction. The maximum vibration is measured as the peak particle velocity (PPV), in inches per second and recorded for each monitoring instrument. These vibrations measured at different distances are plotted (typically PPV on the y-axis versus Distance or Log Distance on the x-axis).

Generally, the magnitude of vibration will decrease the further it is away from the source of vibration. After a minimum distance from the source, the magnitude of the vibrations is typically observed to decrease in a linear fashion. With this charted data and support from your monitoring professional, you can understand how the vibrations dissipate and estimate what level of vibration may still be experienced by a nearby structure.

How can ECS help?

We can evaluate what combination of equipment can be used together or should not be used together. We can also establish what minimum distances should be maintained between certain operations and these structures to reduce the potential for damaging those structures.

What is measured and understanding PPV

The PPV measurement is related to the vibration velocity of the individual soil particles and is not the measurement of not the propagation of the vibration wave itself. Ground particles will vibrate with a variable particle velocity. PPV is the maximum instantaneous velocity of a particle during a specific segment of time.

The displacement or strain induced on a structure and therefore the potential to damage a structure is related to the PPV. The US Bureau of Mines has correlated cosmetic type damages on different types of building materials relative to blasting operations. In addition, there are industry guidelines relative to modern and historic or sensitivity structures based on PPV measurements.

Vibration waves will propagate at a given velocity. Harder materials will propagate the vibration further than softer materials due to differences in dampening and attenuation of these materials. In addition, the soils below a site are not uniform and no two job sites are the same, which makes things more complicated on a project. With this information, you can imagine how challenging and limiting it may be to just rely on predictive equations and published data when trying to evaluate what could happen at your jobsite.

How is PPV measured?

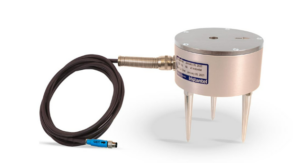

The motion of this particle vibration is three-dimensional, requiring measurements to be measured in three dimensions as well. We utilize triaxial geophone sensors which allow measurements to be made in three axes at the same time. Specific installation locations are selected to assure representative data is collected. The topsoil is removed, then the sensor is installed or orientated in the direction of the source of the vibration, which is then made level and planted in place or weighed down to assure good ground contact is maintained using spikes, burial, or sandbags.

Triaxial Geophone Sensor from Instantel